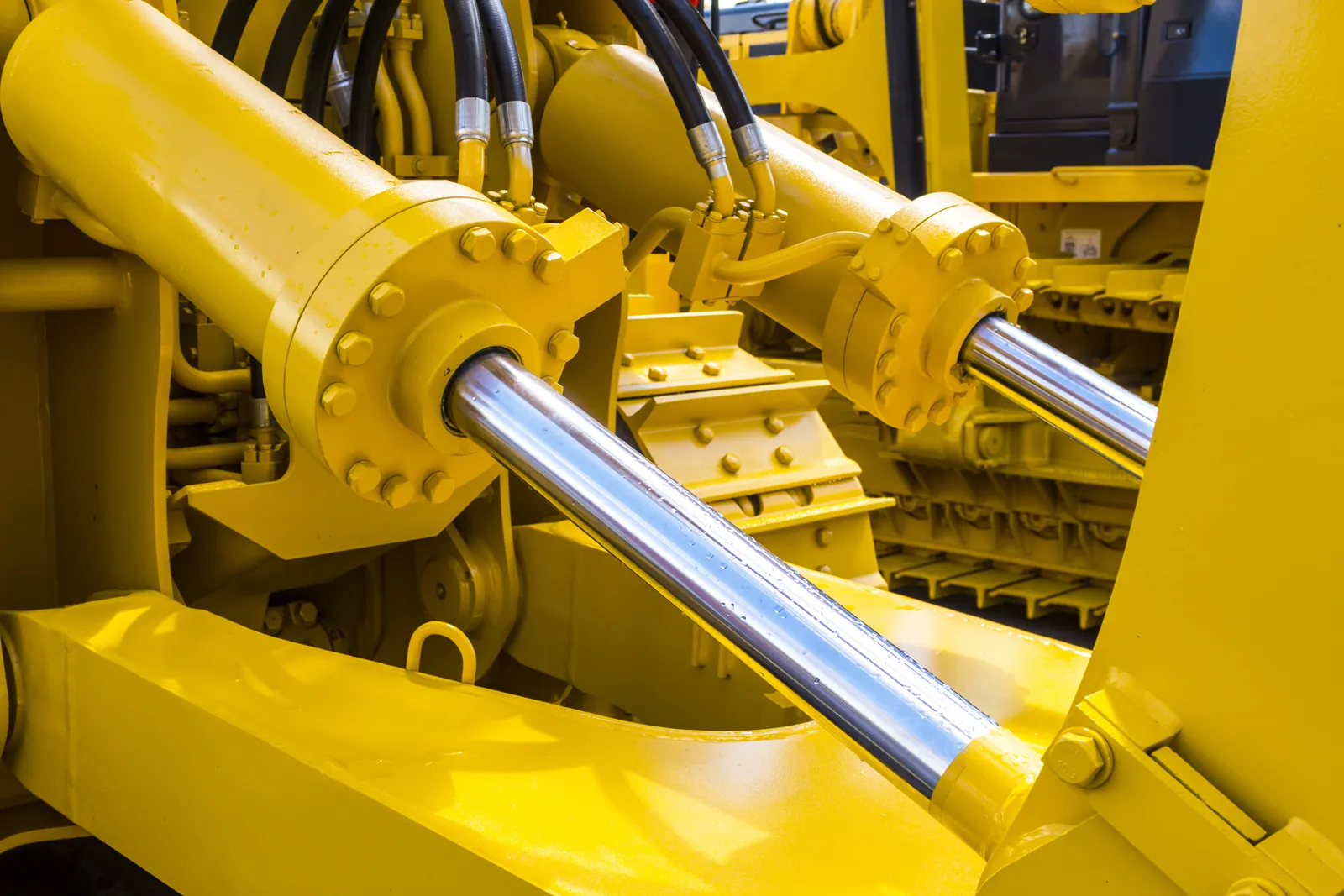

A mining drilling machine is a specialized piece of equipment used to create boreholes for various applications in the mining and exploration industry. These machines play a critical role in open-pit mining and quarrying operations by enabling blast hole drilling, which facilitates efficient rock fragmentation. They are also extensively used in mineral exploration to extract core samples that help geologists analyze underground resources. Additionally, mining drilling machines are employed in environmental assessments and geotechnical investigations to study soil, rock, and groundwater conditions. Their design emphasizes high torque, the capability to drill to significant depths, and adaptability to operate in diverse and challenging terrains—making them indispensable for both surface and underground mining activities.